Mechanical processing technology Heat treatment process

2024-04-30

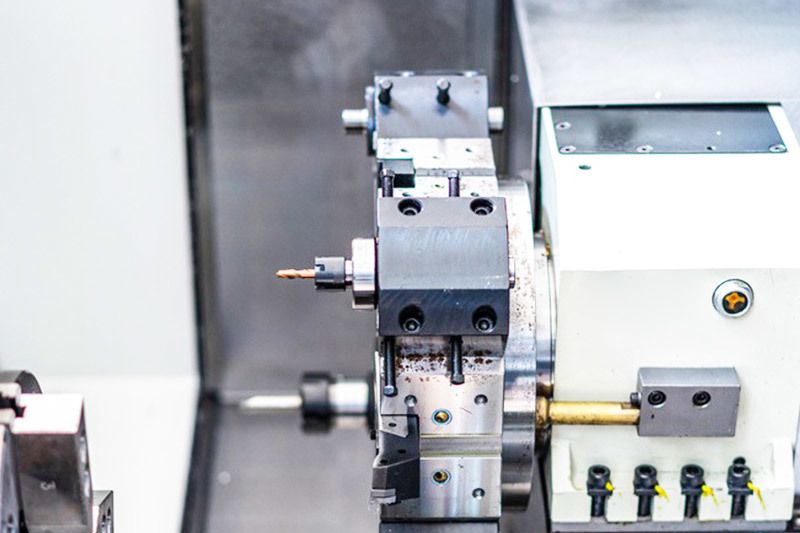

With the development of aerospace, industry, microelectronics industry, modern and biological engineering technology, the demand for/detailed mechanical parts (feature size in micron to millimeter level) is increasingly urgent. The specificity of its structure and shape, the diversification of parts and materials, and the accuracy of size and surface quality have become the obvious characteristics of high-precision mechanical parts and their micro-devices and equipment, and the requirements in terms of use function, material characteristics, structure and shape, and sex are also getting higher and higher.

With the rapid development of modern fine machining, fine machining technology rapid development, slowly emerged a lot of fine machining technology, such as micro fine machining technology, fast forming technology, super machining technology.

Inserting heat treatment in the meticulous machining process at the right time can make the cold and hot processes match well and avoid deformation caused by heat treatment. The arrangement of heat treatment, according to the purpose of heat treatment, can generally be divided:

1. The purpose of preparatory heat treatment is to remove the internal stress generated during the manufacturing process of the blank, improve the cutting performance of metal materials, and prepare for the later heat treatment. There are quenching and tempering, annealing, normalizing, etc., which are generally arranged before and after rough machining. Arranged in the rough machining before, can improve the cutting performance of the material; arranged in the rough machining, is conducive to the removal of residual internal stress.

2, heat treatment should generally be arranged in rough machining, semi-finishing, before and after finishing. Heat treatment with large deformation, such as carburizing and quenching, quenching and tempering, should be arranged before finishing to correct the deformation of heat treatment during finishing; heat treatment with small deformation, such as nitriding, can be arranged after finishing.

Previous article:

The next one:

Other Information

The company will participate in 2024 Yuhuan International Machine Tool Exhibition

10.19-10.22 Wang Huan Machine Tool Exhibition, Yilong Technology Booth: X1-TI0, we are participating!

What are the factors that affect high product components?

Machining has been used in many applications, because the current mechanical manufacturing requirements for output has declined, the requirements for size and shape have gradually increased, and high-product parts have a new development trend. The use of lathes requires different turning methods, but grinding, cutting, milling and other processes can be carried out in one lathe, and the development trend of process integration is more obvious.

Contact Us

E-mail:

915170514@qq.com

Hotline:

400-9922-558

Mobile:

86 135 6688 3318

86 137 0657 8628

Telephone

86-576-88281666