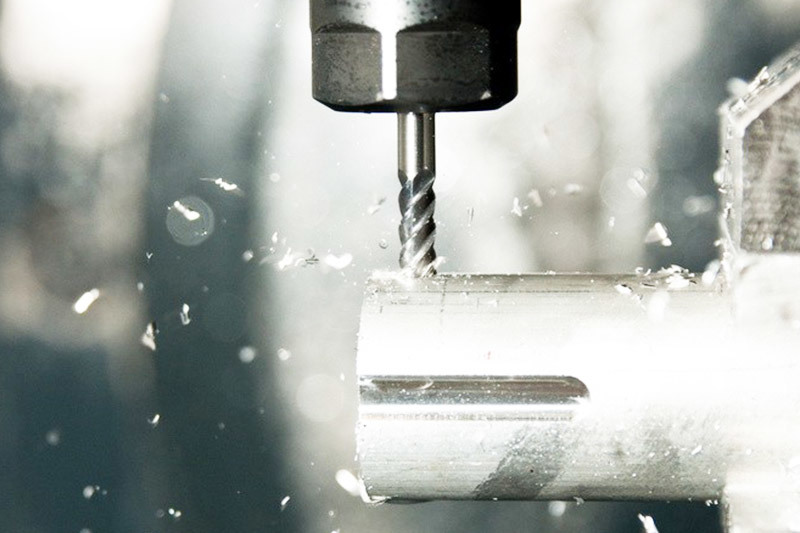

Machining installation sequence and process

2024-04-30

Installation of detailed machining sequence need to pay attention to the problem:

1, to arrange the detailed machining sequence, we need to follow the basic principles of "first surface after hole" and "first coarse after fine.

2. Determine the tool point and tool change point. Once determined, it is not suitable for replacement.

3. For hole systems with high coaxiality requirements, all processing of the hole system shall be completed after one positioning, and then the hole systems at other coordinate positions shall be processed, so as to remove the error generated during repeated positioning and improve the coaxiality of the hole system.

4, according to the tool concentration process for processing, can be a good way to avoid reusing the same tool, reducing the number of replacement tools and time.

High parts used in all walks of life testing equipment-instruments, in the country is mainly used in the instrument and instrument industry.

Compared with ordinary machinery manufacturing, machinery manufacturing has high product technology content (design and production), good processing equipment, high added value, and sales are mostly characterized by small batch differentiation.

Stainless steel materials for machining of mechanical parts:

1. The hardness of the material is moderate, at least one grade lower than the hardness of the machine parts. At the same time, it also depends on what the function of the processed device is and the correct material selection of the machine parts.

2. Requirements for material hardness. For some occasions, the higher the hardness of the material, the better. It is only limited to the hardness requirements of the processed parts. The processed material cannot be too hard. If it is harder than the parts, it cannot be processed.

Previous article:

The next one:

Other Information

The company will participate in 2024 Yuhuan International Machine Tool Exhibition

10.19-10.22 Wang Huan Machine Tool Exhibition, Yilong Technology Booth: X1-TI0, we are participating!

What are the factors that affect high product components?

Machining has been used in many applications, because the current mechanical manufacturing requirements for output has declined, the requirements for size and shape have gradually increased, and high-product parts have a new development trend. The use of lathes requires different turning methods, but grinding, cutting, milling and other processes can be carried out in one lathe, and the development trend of process integration is more obvious.

Contact Us

E-mail:

915170514@qq.com

Hotline:

400-9922-558

Mobile:

86 135 6688 3318

86 137 0657 8628

Telephone

86-576-88281666