2024/04/30

The manufacturing precision of meticulous machining is high, and the surface of the product is smooth during the use of the product, which means that the meticulous machining produced can save a lot of machining work and can be directly used in life. There will be many gray-black round shallow pits on the surface of meticulous machining. The pits will be filled with slag substances before the equipment is cleaned. The degree of these substances will directly affect the quality of our castings.

2024/04/30

Machining Important Index and Structure Design

Meticulous mechanical processing in the production process because of its transition with a small size, so that it will make its mechanical properties good, meticulous mechanical processing can reach its degree of fluidity and does not form bright crystal, the general temperature is 715~740 ℃. The production temperature of meticulous machining can have good fluidity in the process of transferring the melt to a certain extent. In the process of selecting the casting temperature, the equipment needs to be determined according to some factors such as the distance of transferring the melt and the cooling situation in the transferring process.

2024/04/30

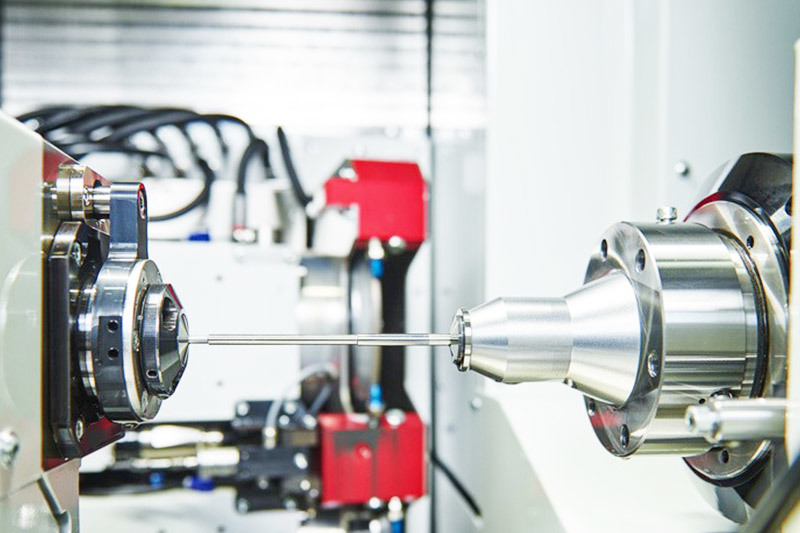

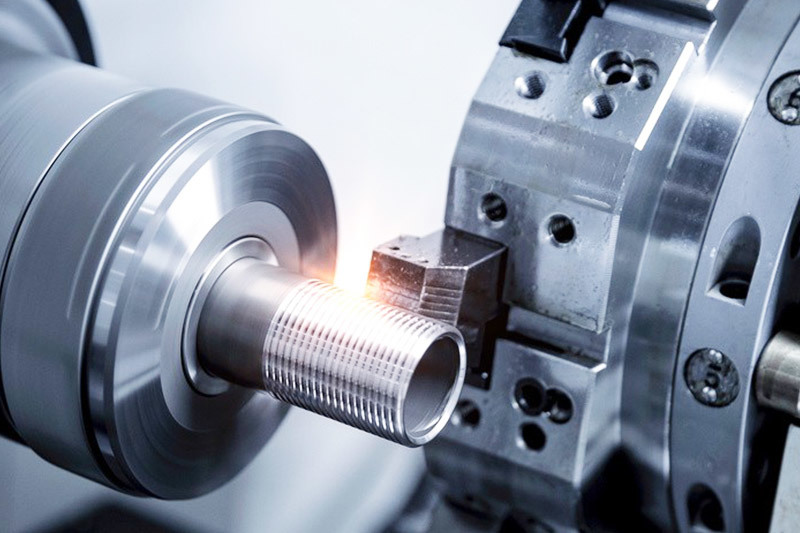

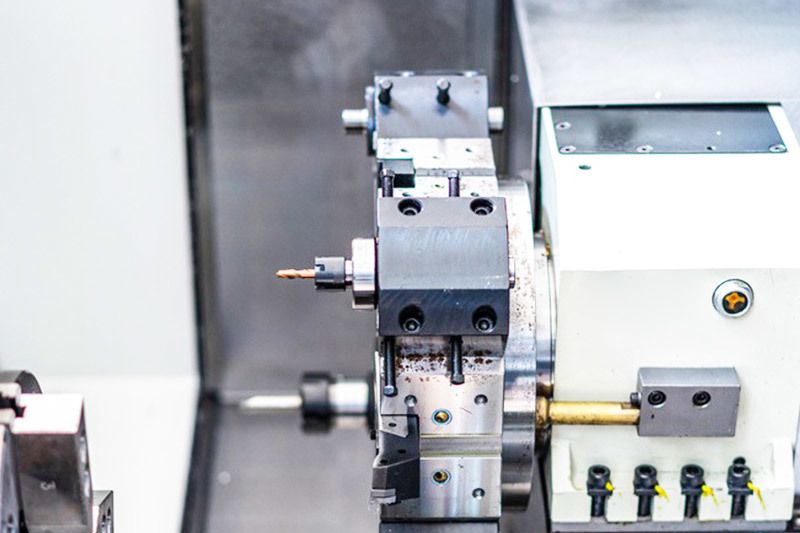

Machining process and technology

Meticulous machining can be divided into upper and lower concave mode, which can be completed through its planing, milling, etching, turning, electric spark and other comprehensive processes. The size of the meticulous machining and the shape of the pit are consistent with the plate edge of the product. When in use, the wax mold is mainly used for industrial wax pressing, so its melting point is not high and its hardness is not high when selecting. When in use, the aluminum alloy material with relatively cheap price and lighter weight is used as the mold.

2024/04/30

Mechanical processing production process

The role of additives in the production process of meticulous machining will no longer be limited to helping the shell to quickly establish wet strength, but also to improve the direction of its investment casting quality, silica sol shell surface quality is good and its high temperature. The high temperature deformation resistance of meticulous machining is good, and the product requires a relatively good precision process. In practice and theory, we should increase the understanding of the meticulous casting process, constantly supplement its technical attempts, and enrich its practical experience.

2024/04/30

Knowledge of machined surfaces and solidification

There will be many gray-black round shallow pits on the surface of meticulous machining. The pits will be filled with slag substances before the equipment is cleaned. The degree of these substances will directly affect the quality of our castings.

2024/04/30

Machining details, forging and casting

In the process of meticulous machining, its mechanical properties are better than cast iron, but the cast iron properties of this material are poor, and the melting point is higher than other materials. There are many problems that need to be paid attention to in the process of processing, mainly because the flow performance of molten steel is relatively poor. In the process of processing, in order to prevent insufficient pouring or cold insulation from meticulous machining, the wall thickness of meticulous machining cannot be less than 8mm. The structural force of the gating system is relatively simple, in the process of using the equipment in the cross-sectional size of cast iron is large, so in the process of processing can also be used in the hot casting mold or dry casting mold.

2024/04/30

Mechanical processing technology Heat treatment process

With the development of aerospace, industry, microelectronics industry, modern and biological engineering technology, the demand for/detailed mechanical parts (feature size in micron to millimeter level) is increasingly urgent. The specificity of its structure and shape, the diversification of parts and materials, and the accuracy of size and surface quality have become the obvious characteristics of high-precision mechanical parts and their micro-devices and equipment, and the requirements in terms of use function, material characteristics, structure and shape, and sex are also getting higher and higher.

2024/04/30

Machining installation sequence and process

To arrange the detailed machining sequence, we need to follow the basic principles of "surface before hole" and "coarse before fine.

Other Information

The company will participate in 2024 Yuhuan International Machine Tool Exhibition

10.19-10.22 Wang Huan Machine Tool Exhibition, Yilong Technology Booth: X1-TI0, we are participating!

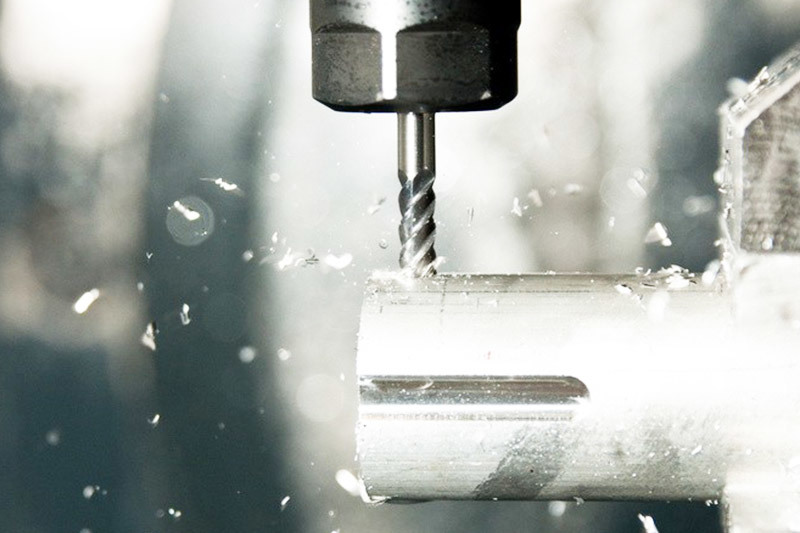

What are the factors that affect high product components?

Machining has been used in many applications, because the current mechanical manufacturing requirements for output has declined, the requirements for size and shape have gradually increased, and high-product parts have a new development trend. The use of lathes requires different turning methods, but grinding, cutting, milling and other processes can be carried out in one lathe, and the development trend of process integration is more obvious.

Precautions and industrial requirements for detailed machining

Meticulous machining is a kind of casting process with little or no cutting. It is a good process technology in the casting industry, and its application is widespread. The reasons for choosing meticulous machining are as follows

Contact Us

E-mail:

915170514@qq.com

Hotline:

400-9922-558

Mobile:

86 135 6688 3318

86 137 0657 8628

Telephone

86-576-88281666